Tergeo-Plus RF plasma cleaner

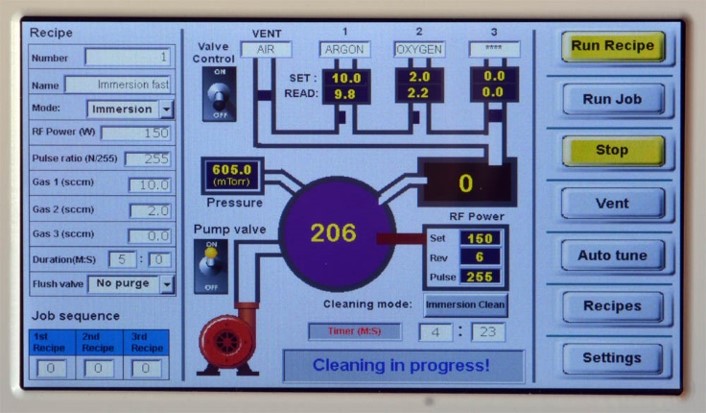

Tergeo-Plus integrates multiple process control technologies to control critical parameters required for optimal plasma etching, plasma ashing and plasma cleaning processes. These include pressure and plasma sensing (see below) and automatic mass flow control of process gas input. Operation is fully automatic, with an intuitive user interface featuring a 7″ touchscreen which make the operation as easy as a tablet device, with the embedded microcontroller supporting 20 customisable user recipes. PIE (Plasma Ion Electron) Scientific’s understanding of the importance of consistency and repeatability in scientific research and small scale production is embodied in the design of the Tergeo series to deliver every day reliability and repeatable performance.

- 150W 13.56MHz high frequency RF power (options for 300W and 500W)

- 160mm ID x 280mm deep chamber

- Patent-pending RF plasma sensor technology

- Direct or remote (option) plasma modes

- Fully automatic operation with 20 recipe support

- Job sequence mode operation for three plasma cleaning steps

- Two mass flow controllers (MFC) regulated gas inputs with option for a third

- Intuitive, touch-screen control

- Pumping options to suit process

- Water vapour delivery option

- Two year warranty

- Expert local support and service

Tergeo-Plus – the basics

Tergeo-Plus is a benchtop RF plasma cleaner, plasma etcher, plasma asher with a quartz glass process chamber with that is 160mm ID and 280mm long to accommodate a 4” wafer rack or one 6” wafer. Tergeo-Plus uses a 150W 13.56MHz high frequency RF plasma supply with auto-matching, which is adjustable from 1 to 150W at 1W intervals. Upgrade options are available for 300W and 500W RF plasma power.

Tergeo-Plus is has two mass flow controller (MFC) regulated gas inputs, a third is available as an option. The standard mode of operation is immersion (direct) where the RF plasma is generated in the main chamber. There is also the option of downstream (indirect) mode where the RF plasma is generated in separate chamber attached to the main chamber – please see below for details.

Tergeo-Plus benefits from unique plasma sensing technology which ensures repeatable and consistent results (see below).

Unique plasma sensing technology

A key advantage of the Tergeo series is the integrated, patent-pending RF plasma sensor technology. The RF plasma strength is measured quantitatively and displayed in real time on the LCD touch screen controller. The operator can use the plasma strength data as feedback to adjust gas flow rates and RF power to give desired plasma cleaning speeds – ensuring repeatable and consistent results for users with beginner or expert levels of experience

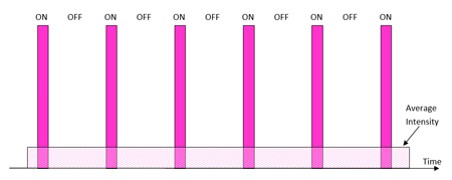

Pulsed RF cleaning mode – for gentler, damage-free plasma cleaning

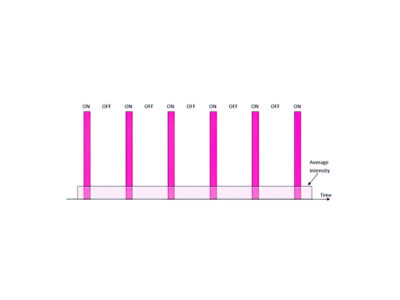

In pulsed operation (option TP104) more gentle RF plasma reaction rates can be maintained, using a lower more “specimen friendly” average power.

Using pulsed operation at 480Hz Tergeo-Plus can reduce “dust” particle formation, trenching, notching and charging. For fluorocarbon PECVD processes the use of pulsed operation can yield rougher surface structure and thereby give greater hydrophobicity

Immersion (direct) and optional downstream (indirect) processing

Immersion mode – for high-speed etching/ashing

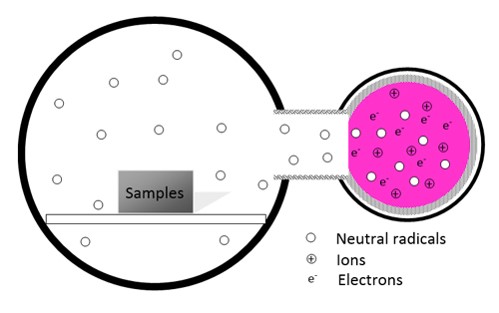

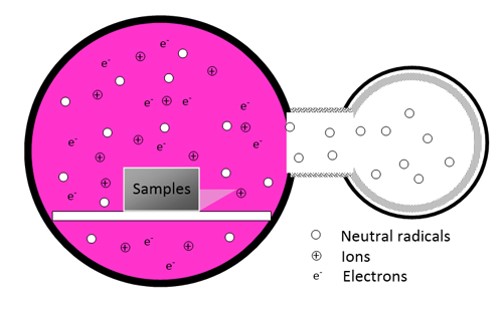

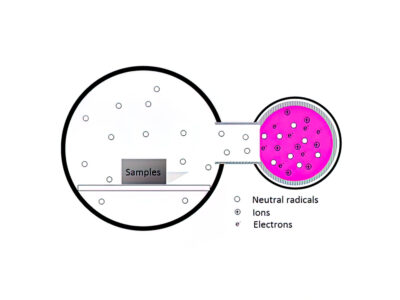

Tergeo-Plus has the capability of two integrated RF plasma sources in one instrument – an immersion (direct) source plus the option of a remote downstream (indirect) source (PIE-TG102). When the plasma is generated inside the main specimen chamber, the immersion mode subjects specimens to both energetic ion bombardment and chemical reactions with neutral radical species. Immersion mode processing is required for high-speed plasma etching, plasma ashing and surface modification.

Downstream mode – for delicate specimens

For specimens such as thin gate oxides, ESD sensitive devices, anti-reflective coatings, graphene, carbon nanotubes, DLC (diamond-like-carbon) and holey carbon support films for TEM, downstream plasma processing mode is recommended. In these cases immersion mode processing could cause irreversible damage to delicate specimens. In remote downstream mode, the plasma is generated by a plasma source inside a second chamber located to the side of the main chamber. In this mode only neutral, lower energy radical species are generated that then diffuse into the main chamber and react with the specimens. This ensures that there is no direct ion sputtering that would result in damage to delicate specimens.

Pumping requirements

Tergeo Plus requires a primary vacuum pump. The Edwards nXDS6i scroll pump is highly recommended when oil-based pumps need to be avoided (i.e. dry pumping). We also offer standard oil-based rotary pumps including a Fomblinised version for applications where high throughputs of oxygen are required.

Please see Ordering Information for details of pumps and accessories

For other instruments in the Tergeo range of plasma cleaners please see here: Tergeo.

PIE-TP105. Upgrade RF plasma power from 150W to 300W ( 13.56MHz, auto-matching)

PIE TP101. Upgrade RF plasma power from 150W to 500W ( 13.56MHz, auto-matching)

PIE-TP102. Integrated, remote RF plasma source for downstream cleaning mode for 2D materials, fragile and other delicate specimens

PIE-TP103. Third MFC regulated gas input

PIE-TP104. Pulsed mode RF plasma for generating controlled extremely weak plasmas and for better control of plasma intensity

A73501983. Edwards nXDS6i dry scroll pump. Ultimate pressure 15~50mTorr, speed:6.2 m3h-1

A73601983. Edwards nXDS10i dry pump. Ultimate pressure 5~20mTorr, speed:12.7m3h-1

A50597000. Silencer for nXDS and XDS5/10

C10514297. NW25 braided flexible pipeline stainless steel 1000mm

PIE-A120. Dust particle filter for using room air as a process gas and/or venting the chamber

PIE-A121. Adjustable external venting flow rate control valve (reduce the venting gas flow rate to prevent the light or powder specimens from being blown away)

Typical applications include:

- Photoresist plasma ashing, descum and silicon wafer cleaning

- PDMS bonding, microfluidics, glass slides and lab-on-a-chip

- SEM/TEM specimen cleaning for hydrocarbon contamination removal

- Medical device activation, sterilization and improved coating adhesion

- Wire bonding, flip-chip underfill, device encapsulation and decapsulation

- Improve bonding of metal-to-metal devices and composites

- Improve bonding of plastics, polymers and composite materials

- Processes requiring a water vapour plasma (using optional PIE-A122 water vapour delivery kit)

- A wide range of other plasma etching and plasma ashing applications

Tergeo Plus tabletop RF plasma cleaner, consisting of:

- Thick-wall (5mm) quartz tube ID:160mm, depth 280mm

- Direct/immersion and downstream/remote plasma sources in one system (optional PIE-TP102 required)

- Plasma emission sensor for quantitative plasma emission intensity measurement

- 150W 13.56MHz high frequency RF supply. Adjustable from 1 to 150W at 1W intervals

- Auto tuning of immersion plasma source

- Fixed matching with optional downstream plasma source

- Continuous (CW) plasma. Duty ratio can change from 1/255 to /255 (CW). Option for pulsed plasma (PIE-TP104)

- 7-inch resistive LCD industrial touchscreen controller

- Fully automatic operation with 20 recipe support

- Job sequence mode operation for three cleaning steps

- Two mass flow controllers (MFC) regulated gas inputs. Option for third MFC (PIE-TP103)

- Premium pressure sensor from MKS Instruments (1E-4Torr to atm)

- Venting/purging port with electronic solenoid valve (Swagelock 1/4″ compression fitting)

- One pumping port with electronic shut-off valve and standard NW/KF25 vacuum port

Note: vacuum pump required (see Pumping Options)

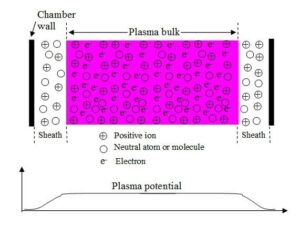

A radio frequency (RF) plasma is an ionised gas phase substance that consists of ions, electrons, and neutral atoms and/or molecules that grossly maintain charge neutrality. Electrons and ions should be close enough so that each of them can influence many nearby charged particles within a radius called the Debye screening length. As a result, charged particles in the RF plasma respond collectively to external electromagnetic fields. With a high density of free-moving ions and electrons, plasma is highly electrically conductive. With the exception of boundary regions between the plasma and electrodes, a plasma contains the same amount of positive and negative charges. There is no space charge within the bulk of the plasma.

Plasma sheath

Electron temperature is usually equal to or higher than that of ions. Since electrons are much lighter than ions, they can escape from a plasma at a much faster speed than ions, providing there is no confining potential barrier. Once electrons are nearly depleted from the boundary interface between the plasma and electrodes or specimen, a region with only positive ions and neutrals will be formed. This usually dark boundary region is called plasma sheath. Positive charges in the plasma sheath can push more ions to diffuse out of the plasma. It also creates a potential barrier to prevent electrons from diffusing out of the plasma. Eventually, the loss rate of electrons and ions will reach an equilibrium state. The plasma sheath also creates a positive plasma potential with respect to the grounded chamber walls. The voltage drop across the plasma sheath can accelerate ions and create an ion sputtering effect in many applications.

How an RF plasma is generated

Electrons and ions in plasmas can disappear through diffusion or recombination. To sustain a stable RF plasma, external excitation is required to create more electrons and ions so that their creation rate can reach a balance with the loss rate. Most RF plasma generation methods rely on heating free electrons to high enough energy to break down neutral atoms or molecules into ions and electrons.

PIE Scientific specialise in developing advanced plasma systems for plasma etching, cleaning, surface treatment, ion and electron beam production applications. The company was founded by alumni of the Plasma and Ion Source Technology group in the Lawrence Berkeley National Laboratory. After 15 years of experience in developing advanced semiconductor capital equipment in Silicon Valley, they realized that many existing low-cost plasma cleaners and plasma treatment systems were still using decades-old technology. Therefore, they decided to bring state-of-the-art plasma technology developed for the semiconductor industry and nuclear research into affordable plasma instruments. Their SmartClean™ technology has been well-received by customers.

Ordering information:

Pump options

An Edwards scroll pump and silencer/filter and flexible metal vacuum hose is recommended.

-

Edwards RV3 rotary vacuum pump (including Ultragrade oil) with 2m UK mains lead

Edwards RV3 two stage rotary vacuum pump

Price On Request £2,308.25 Add to basket -

EMF10 mist filter

Edwards EMF10 oil mist filter suitable for use with an RV3 pump. Supplied with NW25 clamp, centering ring and O- ring- NW25 to 3/4 inch BSP adaptor.

£318.50 Add to basket -

Edwards nXDS10i dry scroll pump

Peak pumping speed 11.4m3/hr (6.7cfm). Ultimate pressure 0.007 mbar (0.005torr) Pump controller with push button control Remote serial and parallel control plus USB service interface Supply 100-127/200-240V (+/- 10%) 1ph 50/60Hz without user intervention Inlet port: NW25. Exhaust port: NW25

Price On Request £5,545.75 Add to basket -

Edwards nXDS6i dry scroll pump

Peak pumping speed: 6m3/hr (3.53cfm) Utimate pressure: 0.02mbar (1.5e-2torr) Inverter drive with push-button control Remote serial and parallel.control and USB interface Supply: 100-127/200-240V 1ph 50/60Hz without user intervention Inlet port: NW25. Exhaust port: NW25

Price On Request £4,434.50 Add to basket -

Silencer for nXDS and XDS5/10

Silencer for nXDS and XDS10i scroll pumps (not connected to a house exhaust system). Silencer also offers exhaust filtration.

£269.50 Add to basket -

NW25 braided flexible pipeline stainless steel 1000mm

Flexible metal vacuum hose with connecting clamps, O-rings and O-ring carriers

£300.38 Add to basket

Options and accesories for Tergeo-Plus

-

Third MFC regulated gas input

Third MFC regulated gas input

Price On Request Read more -

Pulsed mode operation

Pulsed mode operation for generating extremely weak plasmas suitable for fragile specimens, such as 2D materials and TEM carbon grids

Price On Request Read more -

Spare quartz sample shelf for Tergeo-Plus

Spare quartz specimen shelf for Tergeo-plus plasma cleaner.

Price On Request Read more -

Spare front door O-ring seal for Tergeo-plus

Spare front door O-ring seal for Tergeo-plus.Teflon coated and highly resistant to plasma

Price On Request Read more -

Upgrade from standard 150W to 500W RF power supply

Power upgrade to increase RF power from 150W to 500W, 13.56MHz

Price On Request Read more -

4 inch wafer holder

4 inch wafer holder, made of aluminium

Price On Request Read more -

6 inch wafer holder

6 inch wafer holder, made of aluminium

Price On Request Read more -

Quartz wafer boat

4 inch quartz wafer boat, 50 slots, for Tergeo-plus and Tergeo-Pro system

Price On Request Read more -

Water vapour delivery kit

Water vapour delivery kit for generating water vapour plasma, creating super hydrophilic surface with high density OH* functional groups on surface.

Price On Request Read more -

Integrated remote plasma source

Integrated remote plasma source for downstream cleaning mode for 2D materials and other delicate samples

Price On Request Read more -

Upgrade from standard 150W to 300W RF power supply

Upgrade Tergeo-Plus RF power from 150W to 300W, 13.56MHz.

Price On Request Read more