ClinoStar

The ClinoStar is a clinostat CO₂ incubator which allows you to culture cells in 3D.

The ClinoStar from CelVivo pushes the frontiers of 3D in vitro cell culture models.

The innovative clinostat CO2 incubator creates an environment to promote the growth and maintenance of large 3D tissue mimetic structures, whether they are spheroids, organoids or other aggregates.

Low Shear and Active Diffusion

Growing 3D structures evolve in an anti-gravity but physiologically relevant growth environment, uniquely allowing the recapitulation of a truer function, structure and architecture after just 3 weeks. Spheroids can undergo complete maturation and this can be maintained for up to 1 year.

Create Optimal Spheroids

The unique design of the ClinoStar enables you to generate optimal spheroids, which mimic in vivo tissues, for relevant phenotypical, transcriptomic and biomarker assays. The ideal environment for both research and drug testing.

Adjustable Rotation Speeds

Create a dynamic environment for cells, increasing nutrient and oxygen delivery, whilst augmenting the removal of waste products. This active diffusion recreates what is seen in vivo and eliminates dead zones within your culture.

User Friendly Operation

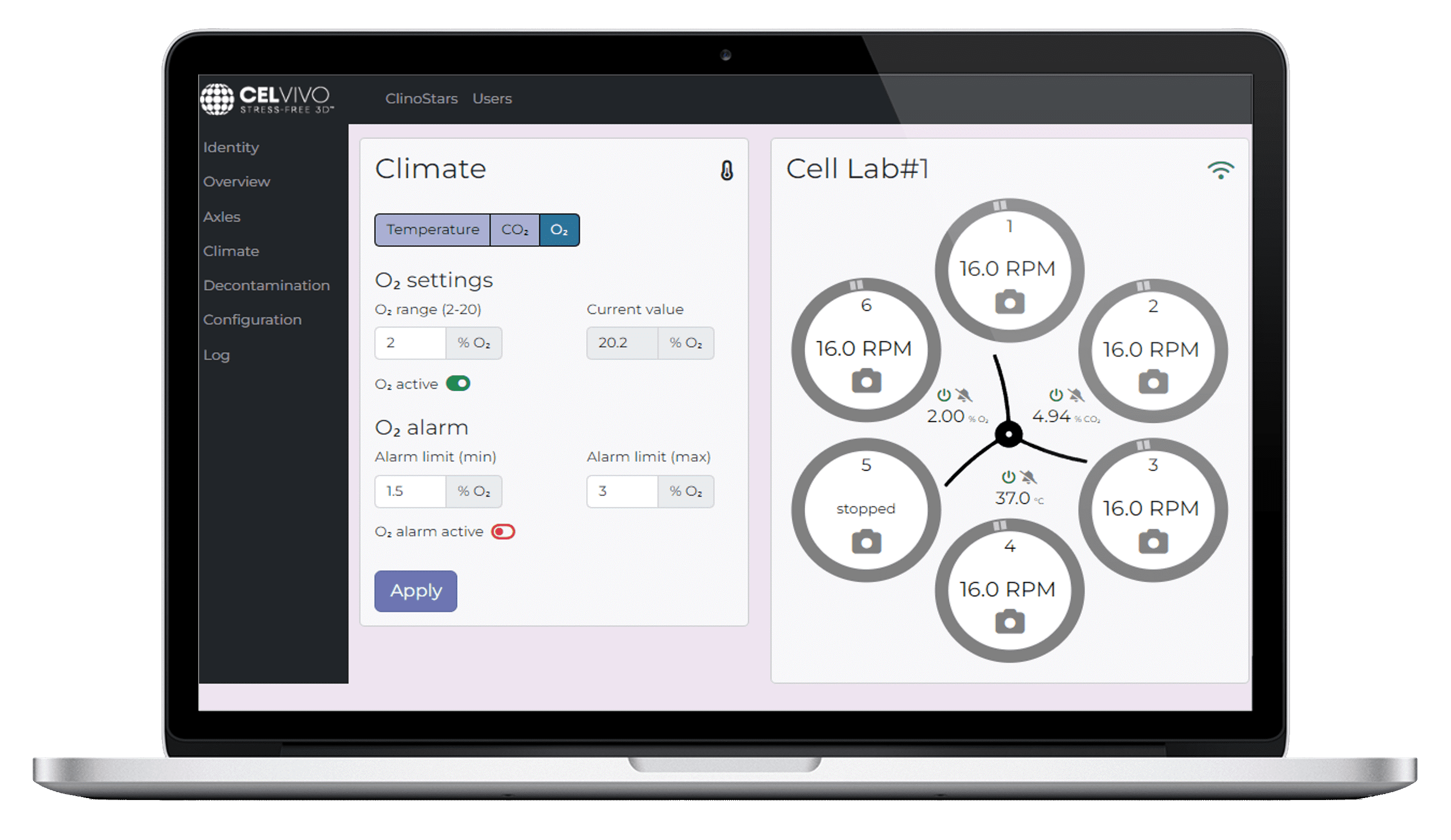

Ethernet and/or tablet controlled with intuitive software and integrated high quality cameras enables users to remotely adjust each of the 6 clinostat motors independently based on user observations

£0.00

• Up to 6 ClinoReactors containing the cells of interest, are gently rotated inside the ClinoStar under precise CO2, humidity and temperature control

• Rotation acts as a counterbalance to gravitational forces, enabling single cells to form spheroids

• Over time the cells mature to form tissue-like moulds, before maturing into 3D cell models with functions similar to those seen in vivo.

• As they evolve, the rotational speed is adjusted so that the cells remain in orbit

• Unlike alternative approaches, the adjustable rotation speeds enable the creation of a dynamic environment for the cells, increasing nutrient and oxygen delivery to the spheroids, whilst aiding with the removal of waste products

• This active diffusion recapitulates what is seen in vivo, thereby increasing cellular health and function

• Each ClinoReactor has an associated motor which slowly spins the reactor. Each motor can be individually controlled by the included tablet.

• A ventilation fan in the chamber ensures a uniform environment within the chamber.

• 6 individual cameras allow you to monitor each ClinoReactor in real time.

• Decontamination of the chamber is provided by integrated UV-C LEDs

• The door has a push to open mechanism, so your hands are free to hold the ClinoReactors.

• Multiple ClinoStar systems can be controlled by the included tablet and up to 3 can be stacked.

• Event Log.

• Potential to assign reactors to individual users.

Optional Hypoxia Upgrade:

- Ability to regulate the level of oxygen from atmospheric to 2%

- Rapid attainment of the set point for the media’s oxygen level is achieved through active gas exchange between the ClinoStar and the ClinoReactor humidification chamber.

- The ClinoReactor’s semi-closed environment temporarily preserves hypoxic conditions for operations within a regular atmospheric oxygen environment (21%). This simplifies short-term handling procedures, such as microscopy observation and documentation.

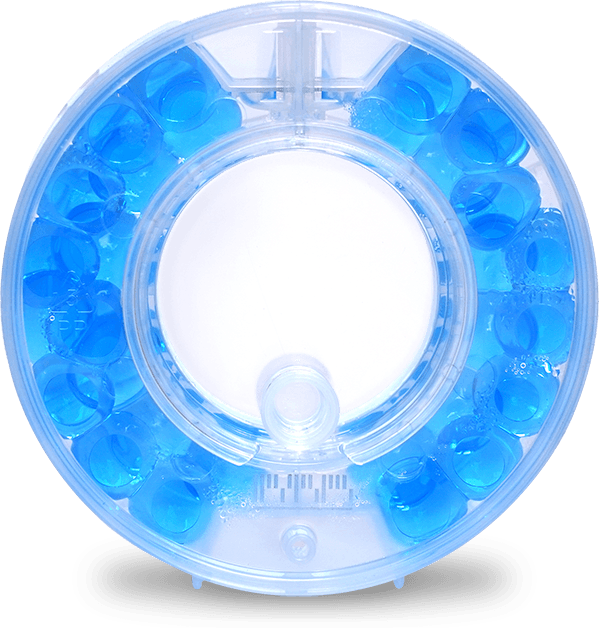

• An individually wrapped all in one bioreactor with 10ml growth culture chamber.

• The front wall can be clicked on and off, providing full access to the chamber as with a petri-dish.

• The vents in the top ensure a constant flow of air over the membrane allowing CO2 to be in equilibrium with the media inside the cell chamber.

• An in-built humidification system minimises the risk of infection and keeps the volume constant inside the incubation chamber.

• Integrated feet allow the ClinoReactor to stand unsupported for media exchange.

• Media exchange is carried out via the top vial and can be performed in a couple of minutes.

• The front port allows for easy sampling of spheroids.

Enhanced cell proliferation with reduced doubling time. Grow larger, more uniform spheroids with much closer to in vivo characteristics. VIEW REFERENCE

Increased cell viability and healthier spheroids. ATP monitoring in ClinoStar cultured spheroids shows increased metabolic activity with spheroid size. VIEW REFERENCE

Superior physiological performance. Monitoring both cholesterol and urea levels in healthy hepatocyte spheroids (C3A) cultured with the ClinoStar closely resembled healthy liver tissue function VIEW REFERENCE

Unparallel organoid ultrastructure. ClinoStar cultured organoids show all of the organelles that are found in eukaryotes (nuclei, mitochondria, ER, and tight junctions). With C3A organoids, we also see bile canaliculi and microvilli, rarely seen with 2D culture, and glycogen granules as the storage molecules of glucose in the liver VIEW REFERENCE

Better post translational modifications. With ClinoStar grown primary and HepG2/C3A spheroids, there is clear evidence of histone clipping. This is rarely seen in 2D cultured cells VIEW REFERENCE

Truer metabolic profiling. Relative to 2D cultures, spheroids derived using the ClinoStar system show enhanced metabolic and structural properties. The activity of metabolic pathways (Glycolysis, TCA and OXPHOS) were better represented in a C3A spheroids, as did the structural properties of actin, microtubules and keratin architecture. VIEW REFERENCE

Exterior Dimensions (w x h x d) – 450 x 420 x 250 mm

Internal Chamber Diameter – 305 mm

Internal Chamber Depth – 80 mm

Temperature Control Range – RT + 6 ˚C up to RT + 30 ˚C

Temperature Regulation Accuracy – ±0.25˚C

CO2 – 0-10%

CO2 Measurement – IR

Electrical Data – 110-230V, 50/60Hz, 30-65W single phase

Cameras – 6 x 5MP, one for each ClinoReactor

Decontamination – 30mA UV-C LED (only when door is closed)

Motor Speed Range – 1.5 – 100 rpm (each ClinoReactor can be individually controlled)

Speed Accuracy – ±1%

Direction – Clockwise and Anticlockwise

CO2 Supply – Max 1 bar, 8mm connection hose