Desiccant storage box

Micro-Tec reusable desiccant boxes consist of a small, perforated plastic box filled with silica gel. The base and the top of the plastic box contain slots for air circulation, silica gel sorbent captures moisture while the silica gel is conveniently held inside the box. Ideal for lowering humidity in closed containers and for protecting sensitive specimens, parts, materials and assemblies from moisture.

Micro-Tec reusable desiccant boxes have dimensions of 55 x 55 x 23mm and contains 45g of either orange indicating or white non-indicating silica gel desiccant. Orange indicating silica gel is also available in bulk in a 500g container.

Ideal for use in Micro-Tec polycarbonate vacuum desiccators.

Silica gel comes in the form of 2-5mm glass beads and contains 2.5nm pores, which translates to the huge surface area of 800m2/g. Silica gel readily adsorbs water on its vast surfaces and reduces the humidity in a closed container until it becomes saturated. Works best at room temperatures and at high humidity but will work in the full 0-100°C range. The Micro-Tec desiccant pack can be used in smaller desiccators up to 100L – for larger containers use multiple Micro-Tec packs. The orange indicating material changes from orange (dry) to dark green (8-10%) water, maximum capacity is around 40% water. Both the orange indicating, and white non-indicating silica gel can be easily regenerated by heating at 140°C in an oven or by microwaving for 3 x 3 minutes at 900W maximum. Available as:

- Micro-Tec DB5 orange indicating silica gel desiccant box

- Micro-Tec DB5 orange indicating silica gel in bulk form, 500g container

- Micro-Tec DB6 white non-indicating silica gel desiccant box

Indicating Silica Gel Desiccant

Introduction

Silica gel is one of most commonly used desiccants (sorbents) and consists of nano-porous silicon dioxide (SiO2). Silica gel comes in the form of glass beads with an average size of approximately 3mm (1/8”). In this state it is an indurated, non-toxic and non-flammable material. The open nano-porous structure with an average pore size of 2.4 – 2.5nm translates to a surface area of 800m2/g. Due to this open nano-porous structure, it is able to adsorb and hold water molecules (moisture) up to a maximum of 40% of its own weight. Silica gel beads do note swell since the moisture is adsorbed at the surface.

As a result silica gel can reduce the relative humidity (RH) in a closed container to levels below 40% RH until the silica gel is saturated with water. Silica gel works in the temperature range from 0-100°C, but it performs best at room temperatures and medium to high humidities: 60-90% RH. Silica gel can be easily regenerated (dried) by heating.

Types of Silica Gel

Non-indicating silica gel beads have a glass like appearance and are clear to milky white; there is no indication as how much moisture has been adsorbed.

Indicating silica gel has been loaded with an colour changing indicator which shows when the silica gel becomes saturated. There are two types of indicating silica gel:

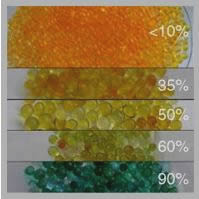

- Orange indicating silica gel contains methyl violet which shows an orange colour when dry and changes its colour to dark green when saturated. We offer the orange indicating silica gel since this is considered a non-toxic material.

- Blue indicating silica gel contains cobalt (II) chloride which shows dark blue when dry and pink when saturated. Blue indicating silica gel is considered to be toxic and carcinogenic in Europe and has to be treated as toxic material.

Indicating and non-indicating silica gel can be mixed to help determining when the silica becomes saturated. Silica gel displays its full colour change when it is saturated by holding 8-10% of its weight in moisture; at that point the silica gel should be changed or regenerated. However, the silica gel is still functional until it has adsorbed up to 40% of its weight in moisture. This means that there is large safety margin after the colour has changed.

Regeneration of indicating Silica Gel

Bulk silica gel can be easily regenerated (dried) by driving off the adsorbed water. This can be done in two ways:

- Heat the silica gel in an oven at 130-145°C for 2-3 hours

- Microwave at maximum 900 watt with intervals of three minutes until the colour indicates dry.

Spread the silica gel in a microwave safe and oven compatible shallow tray to speed up the drying process.

Caution: do not use temperatures above 150°C and do not use a microwave oven power over 900W.

If silica gel is packed in containers, extra care is needed:

- When packed in boxes; remove from plastic box and regenerate

- When packed in Tyvek envelopes; maximum drying temperature is 120°C

- When packed in cans of capsules follow instructions from the manufacturer

Moisture adsorption capacities of different sorbent types showing the response and capacity.

Ordering information:

-

Reusable desiccant box with orange indicating silica gel

Micro-Tec DB5 reusable desiccant box with orange indicating silica gel- 55x55x27mm (each)

£6.36 Add to basket -

Micro-Tec DB6 reusable desiccant box with white non-indicating silica gel – 55 x 55 x 23mm

Micro-Tec DB6 reusable desiccant box with white non-indicating silica gel – 55 x 55 x 23mm (each)

£5.71 Add to basket