EM-KLEEN RF plasma cleaner

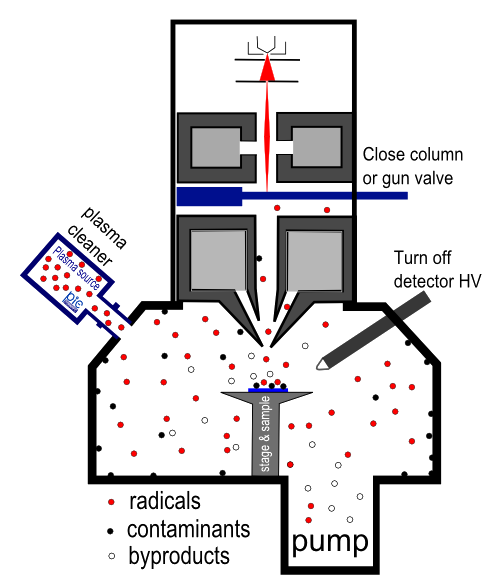

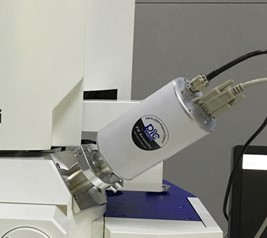

EM-KLEEN is a technologically advanced RF plasma cleaner used to clean vacuum chambers of electron microscopes and other analytical instruments, including SEM, FIB, FIB/SEM, TEM, XPS and SIMS. EM-KLEEN comprises an easy to use, resistive LCD touchscreen controller with embedded microcomputer and a remote plasma source which is installed on the vacuum chamber.

PIE Scientific is the first to introduce technology to integrate a pressure sensor and plasma sensor into the plasma tube. With real-time feedback from the pressure sensor and plasma sensor EM-KLEEN can automate the whole process to ensure optimal operation on any vacuum system. No manual adjustment is required!

- High efficiency RF plasma discharge technology with inductively coupled plasma source

- High speed and gentle plasma cleaning modes with easy exchangeable aperture

- Unique monitoring of plasma strength – assists the user to set up optimal recipes

- Instant plasma ignition at extremely low pressures – guaranteed plasma ignition

- Electronic gas flow with pressure sensor feedback control – user can directly control pressure

- 75W RF power at 13.56MHz – optimal for most applications

- Microcomputer control with touchscreen user interface – ease of use, reproducibility

- Remote PC control through RS232/RS485 – intuitive user interface

- Intelligent “Safe” and “Expert” modes with user customizable warning messages – ideal all levels of expertise

- Supports 60 customisable recipes

- Active fan cooling – high power, high speed cleaning

- Over temperature interlock – system protection

- Compact, portable controller – easily moved between different systems

- Two year warranty

Compact, downstream plasma cleaner

EM-KLEEN packs a lot into a very compact unit, including integrated Pirani pressure sensor, automatic gas flow controller, plasma strength sensor, temperature sensor and a cooling fan. EM-KLEEN can easily be pumped down to low 10-7 mbar vacuum.

The system flow controller automatically adjusts gas flow rate to maintain user-specified pressure levels inside the plasma cleaner chamber, with a miniature pressure sensor constantly monitoring the chamber pressure. The sensor can be used as a safety interlock trigger in “safe” operation mode and to count specimen loading events using the SmartSchedule™ feature.

EM-KLEEN has an integrated cooling fan to ensure high-power, high-speed cleaning without causing source overheating. A temperature sensor also provides interlock protection against source overheating during prolonged cleaning at high power. The plasma strength sensor measures the plasma strength in real time, meaning that users are no longer left to guess the plasma status.

SmartSchedule™ – optimising process schedules

SmartSchedule™ is a unique and very useful function built into the EM-KLEEN controller, which allows the user to set up optimal cleaning schedules to suit their workflow. Cleaning schedules are set based on time intervals or the number of specimen loading events. For example, if an SEM or FIB-SEM has no loadlock chamber, then the specimen chamber will be vented during specimen loading. Since the EM-KLEEN plasma cleaner has an embedded pressure sensor, it can detect the pressure events during specimen loading and count the number of specimens processed. Examples of user-defined schedules could be: run recipe 1 after five days or after EM-KLEEN has processed 10 specimens, or run recipe 1 after 60 minutes and repeat the process 20 times.

SEM application example (1)

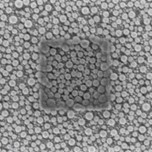

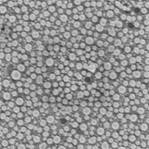

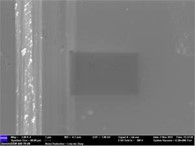

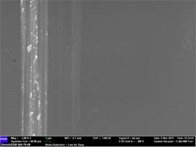

10 minutes scan before (left) and after (right) SEM chamber cleaning using EM-KLEEN

SEM application example (2)

A two-minute plasma clean (left) and after a six-minute plasma clean (right) – no dark scan marks can be seen on the specimen.

In comparison tests EM-KLEEN cleaning rates are typically 3-5 times faster than other systems using the same specimen in the same SEM.

For other instruments in the PIE Scientific KLEEN range and for Tergeo bench top plasma cleaners please see here: KLEEN & Tergeo.

- Accessories

- EM-KLEEN installation examples

- EM-KLEEN - details

- What is a plasma?

- About PIE Scientific

- Dimensions & flange information

PIE-EM101. Upgrade to CF2.75″ flange

PIE-EM102. Rack mounted controller

PIE-EM11. NW/KF40 adaptor for SEM/FIB (JEOL, Hitachi, Tescan, ThermoFisher Scientific/FEI, Zeiss etc)

PIE-EM103. NW/KF40 inline manual bellow valve (allows EM-KLEEN to be moved between SEM/FIBs)

EM-KLEEN consisting of:

- EM-KLEEN RF plasma cleaner- standard configuration with 75W RF power supply

- Tabletop controller with embedded microcomputer and LCD touchscreen user interface

- Remote plasma source (high quality quartz tube) with KF/NW40 vacuum interface

- PC remote control software with intuitive user interface

- 60-recipe support in microcontroller

- 75 Watt RF power supply with fixed RF impedance matching

- Plasma sensor for plasma strength monitor

- Electronic gas flow control with pressure sensor feedback control

- Smart-Schedule feature for automatic cleaning

- Intelligent safe and expert operation mode

- 4.5m (15 feet) high quality high power RF cable; D-Sub 9 PC control cable; D-Sub 15 source control cable.

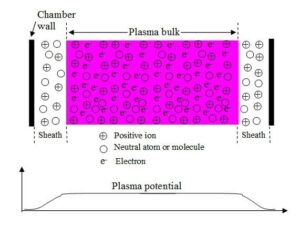

A radio frequency (RF) plasma is an ionised gas phase substance that consists of ions, electrons, and neutral atoms and/or molecules that grossly maintain charge neutrality. Electrons and ions should be close enough so that each of them can influence many nearby charged particles within a radius called the Debye screening length. As a result, charged particles in the RF plasma respond collectively to external electromagnetic fields. With a high density of free-moving ions and electrons, plasma is highly electrically conductive. With the exception of boundary regions between the plasma and electrodes, a plasma contains the same amount of positive and negative charges. There is no space charge within the bulk of the plasma.

Plasma sheath

Electron temperature is usually equal to or higher than that of ions. Since electrons are much lighter than ions, they can escape from a plasma at a much faster speed than ions, providing there is no confining potential barrier. Once electrons are nearly depleted from the boundary interface between the plasma and electrodes or specimen, a region with only positive ions and neutrals will be formed. This usually dark boundary region is called plasma sheath. Positive charges in the plasma sheath can push more ions to diffuse out of the plasma. It also creates a potential barrier to prevent electrons from diffusing out of the plasma. Eventually, the loss rate of electrons and ions will reach an equilibrium state. The plasma sheath also creates a positive plasma potential with respect to the grounded chamber walls. The voltage drop across the plasma sheath can accelerate ions and create an ion sputtering effect in many applications.

How an RF plasma is generated

Electrons and ions in plasmas can disappear through diffusion or recombination. To sustain a stable RF plasma, external excitation is required to create more electrons and ions so that their creation rate can reach a balance with the loss rate. Most RF plasma generation methods rely on heating free electrons to high enough energy to break down neutral atoms or molecules into ions and electrons.

PIE Scientific specialise in developing advanced plasma systems for plasma etching, cleaning, surface treatment, ion and electron beam production applications. The company was founded by alumni of the Plasma and Ion Source Technology group in the Lawrence Berkeley National Laboratory. After 15 years of experience in developing advanced semiconductor capital equipment in Silicon Valley, they realized that many existing low-cost plasma cleaners and plasma treatment systems were still using decades-old technology. Therefore, they decided to bring state-of-the-art plasma technology developed for the semiconductor industry and nuclear research into affordable plasma instruments. Their SmartClean™ technology has been well-received by customers.

Dimensions

EM-KLEEN plasma source: diameter 86mm, length 180mm. Controller: W 255mm, H150mm, D 350mm.

Chamber flanges

The standard vacuum flange has a NW/KF40 fitting with adaptors for different SEM ports. A CF2.75″ flange option is also available.

Ordering information:

-

EM-KLEEN plasma cleaner

EM-KLEEN plasma cleaner- standard configuration including tabletop controller with embedded microcomputer and LCD touchscreen user interface.

Price On Request Read more -

NW/KF40 adaptor for SEM/FIB (FEI, JEOL, Hitachi, Zeiss, Tescan etc).

NW/KF40 adaptor for SEM/FIB (FEI, JEOL, Hitachi, Tescan, Zeiss etc).

Price On Request Read more