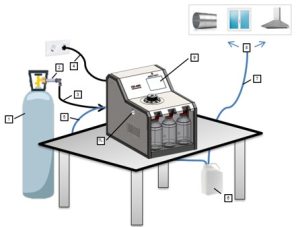

Safematic CDS-020 compact dehydrator and critical point dryer

The unique (patented) Safematic CDS-020 is a fully automatic drying system that allows specimen dehydration and critical point drying in one compact benchtop instrument.

The CDS-020 is designed for processing biological samples for SEM and TEM. Other applications include drying aerogels, hydrogels and small MEMS devices.

Featuring a 60mm diameter x 44mm high vertical specimen chamber, with built-in stirring and viewing window, the CDS-020 save valuable operator time by running the specimen dehydration and drying process concurrently.

The CDS-020 comes with four specimen holders for bulk SEM samples and for 8mm. 12mm and 22m diameter coverslips. Custom holders can be offered on request.

The process chamber is side-lit and has magnetically coupled stirring to ensure complete fluid interchange.

Features:

- Fully automatic, integrated dehydrator and critical point dryer

- Automatic sample dehydration (concentration and time configurable)

- Container for water and two different types of media (ethanol only)

- Automatic critical point drying

- Operation via touch screen graphic display 5.7″.

- Integrated environmentally friendly cooling (no CO2 required during cooling)

- High-strength stainless steel sample pressure chamber ~ Ø60mm x 44mm

- Side sight glass – clear view of specimen chamber

- Magnetically coupled stirrer – ensures optimum fluid exchange

- Software and hardware safety concept with temperature and pressure shut-off

- Chamber lid with twist-lock and lock detection

- Over pressure bursting diaphragm

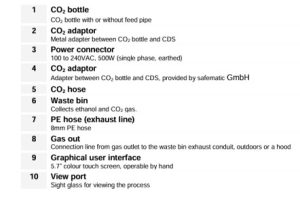

Specimen holders

The CDS-020 comes with four specimen holders for bulk SEM samples and for 8mm. 12mm and 22m diameter coverslips. Custom holders can be offered on request.

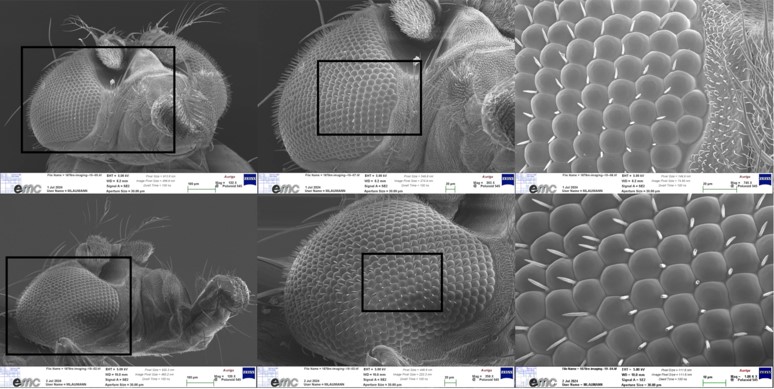

Application example

Drosophila (fruit fly). Dehydration and critical point drying approximately four hours.

| Specifications | CDS-020 |

| Dimensions (L x W x H) | 55 x 37 x 43cm |

| Weight | 42kg |

| Electrical connection | 100 to 240VAC, 50 / 60Hz, max. 500W |

| Noise level | maximum 55dB(A) |

| Chamber dimensions | Ø 60 x 44mm |

| Cup (vessel for sample holders) | Ø 50 x 34mm |

| Chamber volume | 160ml |

| Operating pressure | max. 80bar |

| Bursting pressure | 125bar @ 20°C (bursting membrane) |

| Operating temperature environment | +17 to +27°C |

| Temperature range dehydration | +1 to +24°C |

| Storage temperature | +5 to +40°C |

| Exchange fluid | Ethanol (only), distilled water |

| Exchange fluid consumption | < 1L per run and fluid type (depending on recipe) |

| Transitional fluid | Carbon dioxide (CO2) |

| Gas inlet | 3/8 inch external thread |

| Gas cylinder type | With or without feed pipe |

| Gas cylinder size | ≥ 10L |

| CO2 purity | ≥ 99.9% |

| CO2 consumption | < 0.3kg per run |

| Min. pressure CO2 (Inlet) | 52 bar |

| Waste out | Ø 8mm |

| Waste bin | Container 5L (monitored) |

Located in Switzerland’s St. Gallen Rhine Valley – a region long renowned for expertise in vacuum and coating technology – Safematic GmbH manufactures technology-leading, highly innovative vacuum coaters, dehydration/critical point dryings systems for electron microscopy and thin film applications. Labtech is delighted to offer Safematic sputter coaters, carbon coaters, automatic dryers and accessories to our customers in the UK and Ireland.

Ordering information:

-

Safematic CDS-020 compact drying system

Fully automatic, integrated dehydrator and critical point dryer

Read more

• Automatic sample dehydration (concentration and time configurable)

• Container for water and two different types of media (ethanol only)

• Automatic critical point drying

• Operation via touch screen graphic display 5.7″.

• Integrated environmentally friendly cooling (no CO2 required during cooling)

• High-strength stainless steel sample pressure chamber ~ Ø60mm x 44mm

• Side sight glass

• Magnetically coupled stirrer

Security features

• Software and hardware safety concept with temperature and pressure shut-off

• Chamber lid with twist-lock and lock detection

• Over pressure bursting diaphragm