CCU-010 HV (high vacuum)

Safematic CCU-010 HV compact, fully automatic, high vacuum (oil-free) coating system.

Safematic CCU-010 HV compact, fully automatic, high vacuum (oil-free) coating system.

- Fully automatic, touch screen control with stored recipes

- Integrated turbomolecular (Pfeiffer Hi Pace 80) and membrane pumping (Vacuubrand MD 1 Vario-SP) – no external pump and vacuum hose required

- Superb vacuum performance (to 5 x 10-5mbar in minutes, ultimate vacuum in 10-6mbar range)

- Small footprint (L 570 x W 360 x H 350mm)

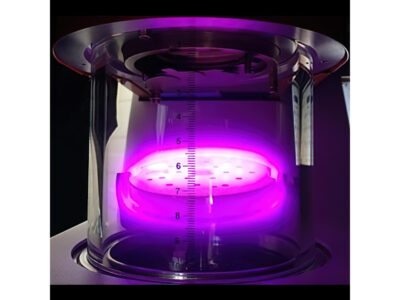

- Glass work chamber 104 mm Ø x 106 mm

- Safety: implosion guard with placement sensor so coater cannot be operated unless the guard is in place

- Specimen table (Ø80 mm) – tilt and height adjustable with holder for 20 standard (13 mm) pin stubs

- Easy access to specimen chamber for cleaning – removed in seconds for complete cleaning

- Integrated terminating film thickness monitoring system. With dual-location (centre oredge) crystal holder to accommodate different sample sizes

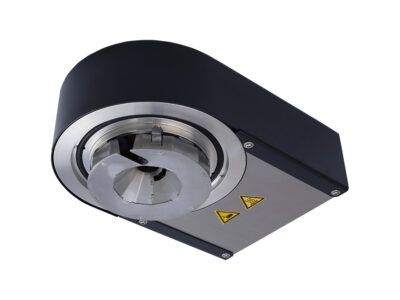

- Optional sputtering module (SP-010) is actively (fan) cooled to allow run times of up to 40 minutes

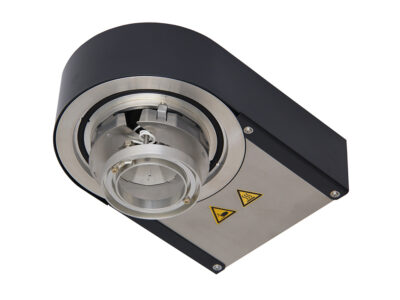

- Optional carbon evaporation module (CT-010) uses a unique carbon fibre spooling system to allow up to 50 coating runs without a source change

- System can be left under vacuum when not in use

- Full range power supply (90-260VAC- 50/60Hz)

£0.00

Safematic CCU-010 HV compact, fully automatic, high vacuum (oil-free) coating system. Key highlights:

- Integrated turbomolecular and membrane pumping (no external pump and vacuum hose)

- Small footprint (L 570 x W 360 x H 350mm)

- Superb vacuum performance (to 5 x 10-5mbar in minutes, ultimate vacuum in 10-6mbar range)

- Safety: implosion guard with placement sensor so coater cannot be operated unless the guard is in place

- Easy access to specimen chamber for cleaning – removed in seconds for complete complete cleaning. Especially important if sputtering and carbon evaporation are being used

- Integrated terminating film thickness monitoring system. With two-location crystal holder to accommodate different sample sizes

- Optional sputtering module (SP010) is actively (fan) cooled to allow run times of up to 40 minutes

- Optional carbon evaporation module (CT010) uses a unique carbon fibre spooling system to allow up to 50 coating runs without a source change

- System can be left under vacuum when not in use.

Note: for a complete working system please select coating head option SP-010 (sputtering), CT-010 (carbon evaporation) or both. Detailed description:

- glass work chamber 104 mm Ø x 106 mm (DN 100 ISO-KF compatible)

- implosion guard and safety monitoring

- table (Ø80 mm)- tilt and height adjustable

- multi-sample holder for 20 standard (13 mm) pin stubs to meet most requirements

- dual-film thickness monitor (FTM) based on a quartz crystal oscillator- usable in two positions (centre/edge)

- integrated membrane pump (Vacuubrand MD 1 Vario-SP)

- integrated turbomolecular pump (Pfeiffer Hi Pace 80)

- full range power supply (90-260VAC- 50/60Hz)

- coating process head interface (gas and electric) including automatic detection

- 5.7“ TFT touch display

- recipe-driven user interface for guaranteed reproducible results

- storage / view of the last ten coating processes

- automatic vent of the system when power failures

- intuitive operator’s software

- graphic display of process data with Windows-based software Coating LAB (option)

- external alarm connector

- USB service interface for easy analysis and software upgrades

- automatic valve control for two process gases and venting

- operating manual

- A comprehensive on-site instrument service prior to the expiration of warranty.

You may also like…

-

ET-010 integrated plasma stage

Plasma cleaning accessory for the pre-treatment (cleaning) or after-treatment (glow discharge effect) of specimens in combination with a coating process.

Price On Request £0.00 Add to basket -

CCU-010 LV (standard vacuum)

Safematic CCU-010 LV compact, fully automatic, standard vacuum coating system.

Price On Request £0.00 Add to basket -

CT-010 carbon coating module

Carbon fibre thread evaporation module with unique thread tracking system, allowing up to 50 coatings without having to break vacuum and replenish the carbon source. Controlled, automatic pulse evaporation modes give optimal coating control and film quality. Easy-fit electrical and pneumatic interface to CCU-010 LV and CCU-010 HV platforms. Includes one 300015 carbon thread on coil 2m.

Price On Request £0.00 Add to basket -

GD-010 glow discharge

Glow discharge attachment for hydrophilic/hydrophobic treatment (rendering) of substrates (e.g. TEM carbon support films). Fully integrated to allow post-treatment of carbon films without the need to break vacuum after carbon coating

Price On Request £0.00 Add to basket